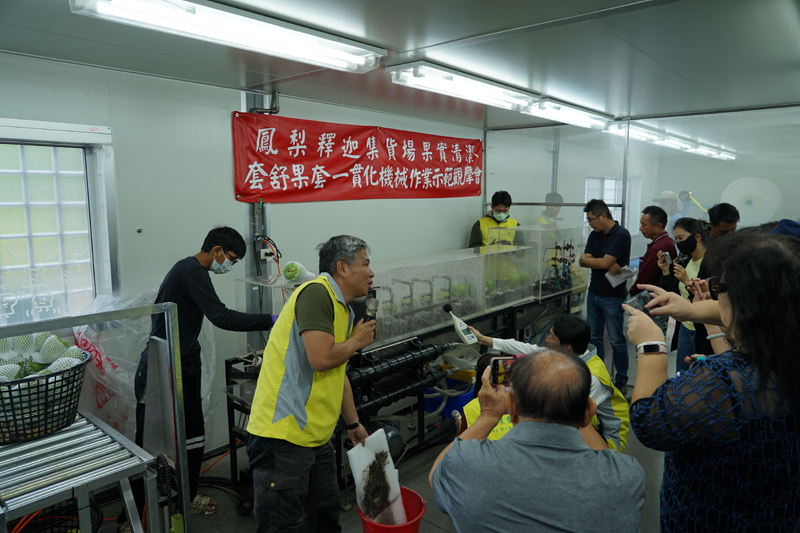

Atemoyas are one of Taitung’s major exports. To save time and money spent on preparing them for export, which, among other things, conventionally requires manually removing mealybugs with blown air, the Taitung District Agricultural Research and Extension Station (TTDARES) of the Ministry of Agriculture has developed an integrated system using a fruit basket lifting device, a crop cleaning device, and a produce sleeving device. The system was shown at the Atemoya Collection Center Cleaning and Sleeving Machinery Demonstration Event, held on the morning of February 21, 2024, at the Sunshine Farm Produce Packaging Plant. The crop cleaner washes the fruits and then blows air on them to remove and collect 100% of the mealybugs before moving the fruits to an isolated area so the bugs may not get back on the fruits. The machinery is about the size of a 20-foot shipping container, and with only three operators, it can process 1,000 boxes (containing a total of about 9,000 fruits) in nine hours. Such quantity manually processed would take an average of 8.3 workers. With the help of the fruit basket lifting device and the produce packaging device, the cost of human labor is greatly diminished. Those who attended were highly impressed with the all-in-one arrangement.